Tronxy Moore X Clay 3D Printer with Enclosure Print Size 255x255x255

The Tronxy Moore X Clay 3D Printer arrives fully assembled, highlighting its cutting-edge ceramic printing features and an aluminum barrel feeding system that guarantees fast printing using the most up-to-date 3D printing technology, enhanced by an electric actuator.

Regarding the Moore X Clay Ceramic 3D Printer:

Frequently Bought Together

Conveniently Delivered Fully Assembled

The Tronxy Moore X Clay 3D Printer arrives fully assembled, enabling you to begin printing immediately upon unboxing. This avoids the inconvenience of having to put it together, appealing to both novices and seasoned users looking to streamline their tasks.

Printing Capabilities are Adaptable and Varied

Crafted for various materials such as clay, ceramics, and liquid substances that flow, this printer provides unparalleled versatility. No matter if you are working on delicate pottery or crafting one-of-a-kind art pieces, the Moore X is effortlessly up to the task.

Printing at High Speed

Witness the swift process of rapid prototyping at a top speed of 150mm/s. The Tronxy Moore X offers efficient production while maintaining top quality, making it perfect for a wide range of projects, whether big or small.

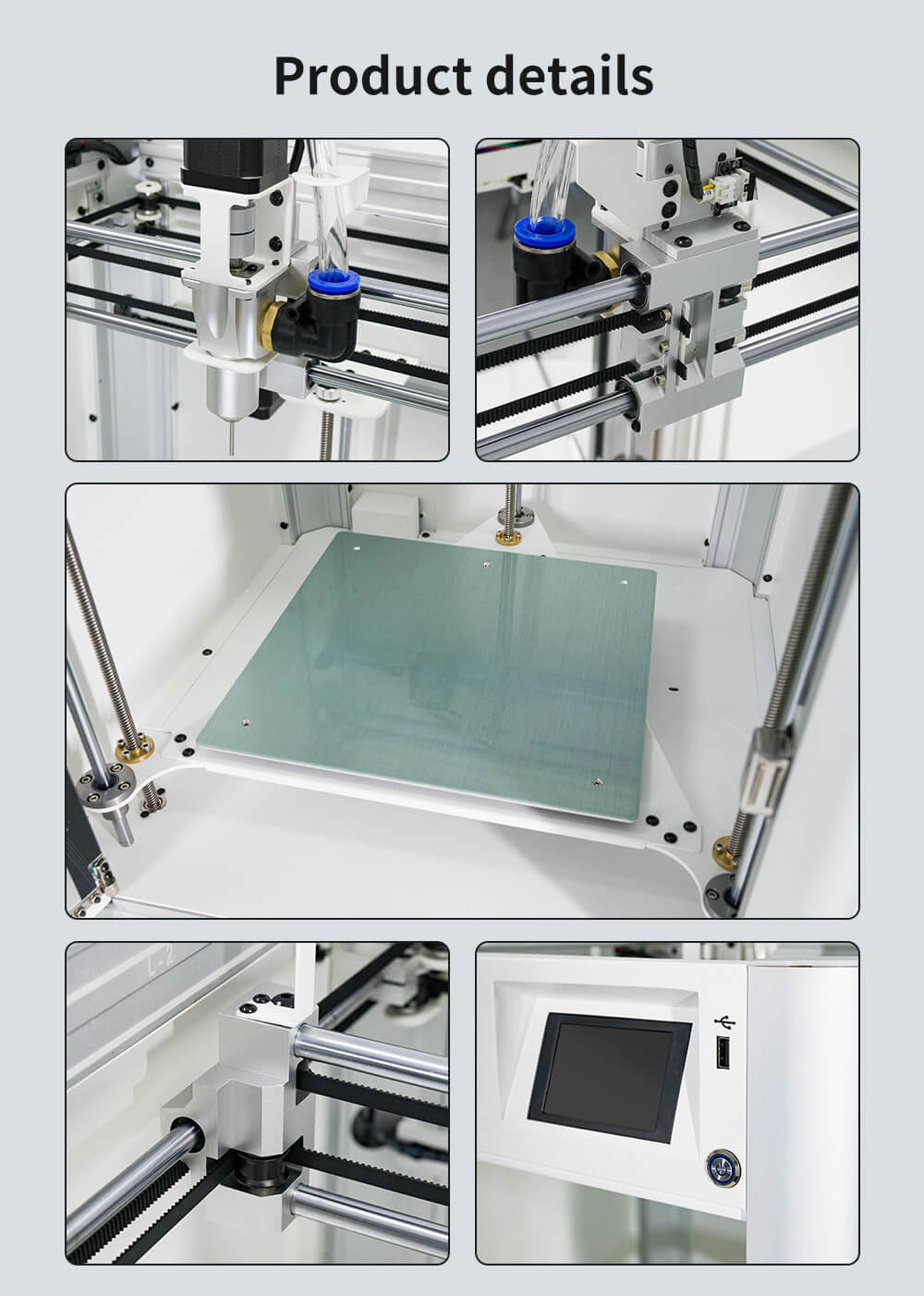

Cutting-edge Feeding Method

This printer ensures a seamless and steady flow of materials with its aluminum barrel feeding system and air compressor. This novel design reduces blockages and makes cleaning easier.

Durable and Reliable Design

The printer is equipped with a sturdy new design and double-axis guide rail to guarantee stability while in use. This particular design elevates accuracy and dependability, ensuring top-notch prints on every occasion.

Intuitive and Easy-to-navigate Interface for Users

The Tronxy Moore X is thoughtfully designed to offer convenience through its USB connection and compatibility with various languages. Just pop in a USB drive to print effortlessly, providing accessibility for users of various expertise levels.

Tronxy Moore X Clay 3D Printer Fully Assembled 3D Printer Ceramic Printing Aluminum Barrel Feeding System High-speed Printing 3D Printing Technology Electric Putter

Tronxy Moore X Ceramic 3D Printer

Efficient Production Of Ceramic Models

Rapid Prototyping And High-speed Printing

The maximum printing speed can be set to 150mm/s, and the layer thickness can be set to 0.3-3mm.

Spiral Feeding Device

No need for an air compressor, making printing lightweight and simple.

Accurate And Efficient Printing

Innovative Core XY structure, printing speed 10-150mm/s, speed up to 300mm/s, achieving high-speed and efficient printing.

USB Connection Insert a USB Drive to Print Directly

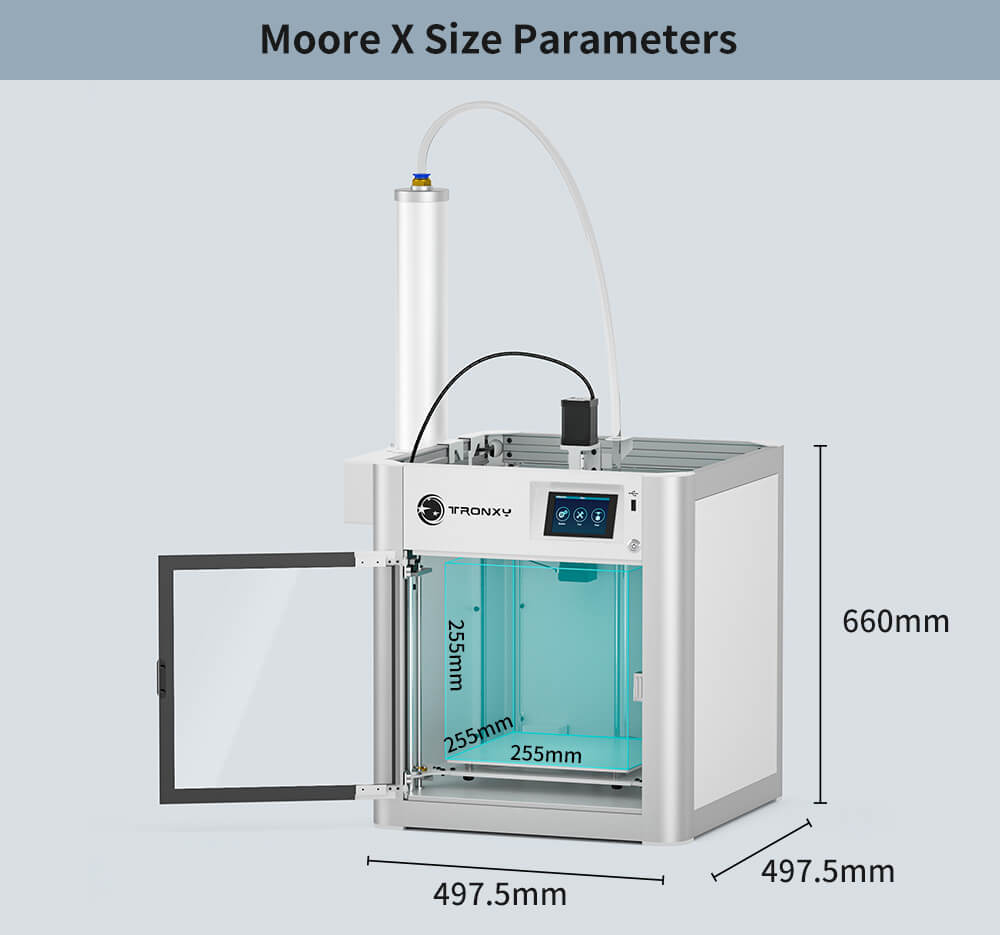

Moore X Size Parameters

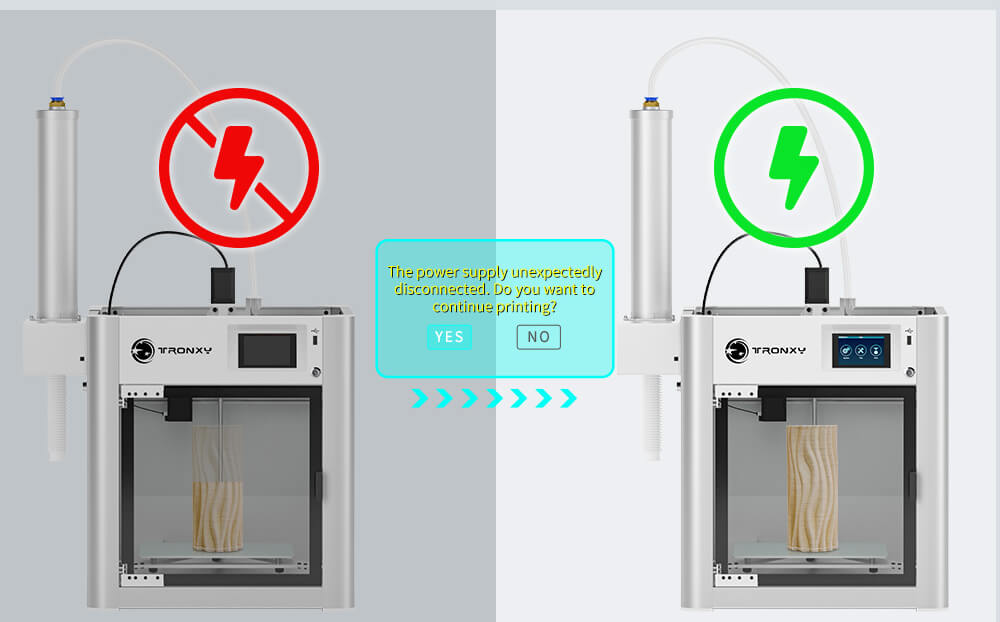

Not Afraid Of Power Outage

We support power outage resumption and pause resumption to address your concerns.

Smoother Metal Guide Rails

The XY axis uses a metal optical axis guide rail, which runs smoothly and stably during rapid movement, and is sturdy and durable.

Watch More

Application Of Ceramic 3D Printing

Moore X Clay Series 3D Printer Parameters

Moore X Clay Series 3D Printer Parameters

(scroll to view all)

| Moore Model | X2525 | X2540 | X3350 | X4060 | X5070 | X6080 |

| Printing Principles | Liquid Deposition Molding | Liquid Deposition Molding | Liquid Deposition Molding | Liquid Deposition Molding | Liquid Deposition Molding | Liquid Deposition Molding |

| Print Size (mm) | 255x255x255 | 255x255x400 | 330x330x500 | 400x400x600 | 500x500x700 | 600x600x800 |

| Print Accuracy | 0.3-3.0mm | 0.3-3.0mm | 0.3-3.0mm | 0.3-3.0mm | 0.3-3.0mm | 0.3-3.0mm |

| Number of Nozzles | 1 | 1 | 1 | 1 | 1 | 1 |

| Positioning Accuracy | x/y: s0.00625mm; z: s0.00125mm | x/y: s0.00625mm; z: s0.00125mm | x/y: s0.00625mm; z: s0.00125mm | x/y: s0.00625mm; z: s0.00125mm | x/y: s0.00625mm; z: s0.00125mm | x/y: s0.00625mm; z: s0.00125mm |

| Nozzle Diameter | 1.0-3.0mm (optional) | 1.0-3.0mm (optional) | 1.0-3.0mm (optional) | 1.0-3.0mm (optional) | 1.0-3.0mm (optional) | 1.0-3.0mm (optional) |

| Barrel Capacity | 0.5L | 0.5L | 0.5L | 5L | 5L | 5L |

| Consumables | Pottery Clay, Porcelain Clay, Purple Clay, etc | Pottery Clay, Porcelain Clay, Purple Clay, etc | Pottery Clay, Porcelain Clay, Purple Clay, etc | Pottery Clay, Porcelain Clay, Purple Clay, etc | Pottery Clay, Porcelain Clay, Purple Clay, etc | Pottery Clay, Porcelain Clay, Purple Clay, etc |

| Printing Speed | 10-150mm/s | 10-150mm/s | 10-150mm/s | 10-150mm/s | 10-150mm/s | 10-150mm/s |

| Movement Speed | 300mm/s | 300mm/s | 300mm/s | 300mm/s | 300mm/s | 300mm/s |

| Equipment Material | Aluminum Profiles, Sheet Metal | Aluminum Profiles, Sheet Metal | Aluminum Profiles, Sheet Metal | Aluminum Profiles, Sheet Metal | Aluminum Profiles, Sheet Metal | Aluminum Profiles, Sheet Metal |

| Device Size (mm) | 497.5x497.5x660 | 497.5x497.5x805 | 572.5x572.5x1243 | 642.5x642.5x2220 | 742.5x742.5x2303 | 851.0x854.7x2416 |

| Screen | 3.5 inch Resistance | 3.5 inch Resistance | 3.5 inch Resistance | 7 inch Capacitive | 7 inch Capacitive | 7 inch Capacitive |

| Platform Material | Tempered Glass | Tempered Glass | Tempered Glass | Tempered Glass | Tempered Glass | Tempered Glass |

| Screw Rod | Ball Screw | Ball Screw | Ball Screw | Ball Screw | Ball Screw | Ball Screw |

| Machine Internal Temperature Control | Constant Temperature | Constant Temperature | Constant Temperature | Constant Temperature | Constant Temperature | Constant Temperature |

| Machine Sealing Method | Fully Enclosed | Fully Enclosed | Fully Enclosed | Fully Enclosed | Fully Enclosed | Fully Enclosed |

| Input | 115-230V 50/60HZ | 115-230V 50/60HZ | 115-230V 50/60HZ | 115-230V 50/60HZ | 115-230V 50/60HZ | 115-230V 50/60HZ |

| Output | 24V/4A DC | 24V/4A DC | 24V/4A DC | 24V/4A DC | 24V/4A DC | 24V/4A DC |

| Ambient Temperature | 8°C~40°C | 8°C~40°C | 8°C~40°C | 8°C~40°C | 8°C~40°C | 8°C~40°C |

| Environmental Humidity | 20%-80% | 20%-80% | 20%-80% | 20%-80% | 20%-80% | 20%-80% |

| File Format | Stl obj dae amf g-code | Stl obj dae amf g-code | Stl obj dae amf g-code | Stl obj dae amf g-code | Stl obj dae amf g-code | Stl obj dae amf g-code |

| Slicing Software | Cura | Cura | Cura | Cura | Cura | Cura |

| Operating Software | Repeater Host Cura | Repeater Host Cura | Repeater Host Cura | Repeater Host Cura | Repeater Host Cura | Repeater Host Cura |

| Operating System | Windows | Windows | Windows | Windows | Windows | Windows |

| Link | USB Interface | USB Interface | USB Interface | USB Interface | USB Interface | USB Interface |

More about Moore X

- Q: What is the Tronxy Moore X Clay 3D Printer?

A: The Tronxy Moore X Clay 3D Printer is a fully assembled printer designed for creating ceramic models. It features an aluminum barrel feeding system and can print with various materials like clay and ceramics. The printing size is 255mm x 255mm x 255mm, making it suitable for medium-sized projects. - Q: How does the feeding system work?

A: This printer uses an air compressor for its feeding system, which helps in pushing the clay or ceramic material through the nozzle. This system ensures a smooth and consistent flow, allowing for high-quality prints without clogging. - Q: What materials can I use with this printer?

A: You can use a variety of materials with the Tronxy Moore X, including clay, ceramics slurry, and red porcelain. This versatility allows you to create different types of ceramic art and pottery. - Q: Is the printer easy to clean?

A: Yes, the Tronxy Moore X is designed for easy cleaning. The new printer head prevents clogging, and the components can be easily accessed for maintenance, making it user-friendly for both beginners and experienced users. - Q: What is the maximum printing speed?

A: The maximum printing speed of the Tronxy Moore X is adjustable, reaching up to 150mm/s. This allows for rapid production of ceramic models, making it efficient for both hobbyists and professionals. - Q: Can I connect the printer to my computer?

A: Yes, the Tronxy Moore X features a USB connection, allowing you to easily connect it to your computer. You can upload your designs directly to the printer for a seamless printing experience. - Q: What happens if there is a power outage?

A: The printer supports power outage resumption, meaning it can pause and resume printing after a power interruption. This feature helps prevent wasted materials and ensures your project can be completed without starting over. - Q: Is the printer suitable for beginners?

A: Absolutely! The Tronxy Moore X is designed with user-friendliness in mind. It comes fully assembled, has an intuitive interface, and includes features that make it easy for beginners to start creating their own ceramic pieces. - Q: What is the size of the printer?

A: The overall size of the Tronxy Moore X printer is 497.5mm x 497.5mm x 660mm. This compact design allows it to fit in various workspaces while still providing a generous printing area. - Q: Where can I buy the Tronxy Moore X Clay 3D Printer?

A: You can purchase the Tronxy Moore X Clay 3D Printer directly from us. Be sure to check for any available discounts or promotions to get the best deal.